Energy Saving Boost for StarCare Maintenance Service

Star Refrigeration has enhanced its industry-leading maintenance programme with the addition of a range of services to help plant operators achieve energy-saving targets and cut costs.

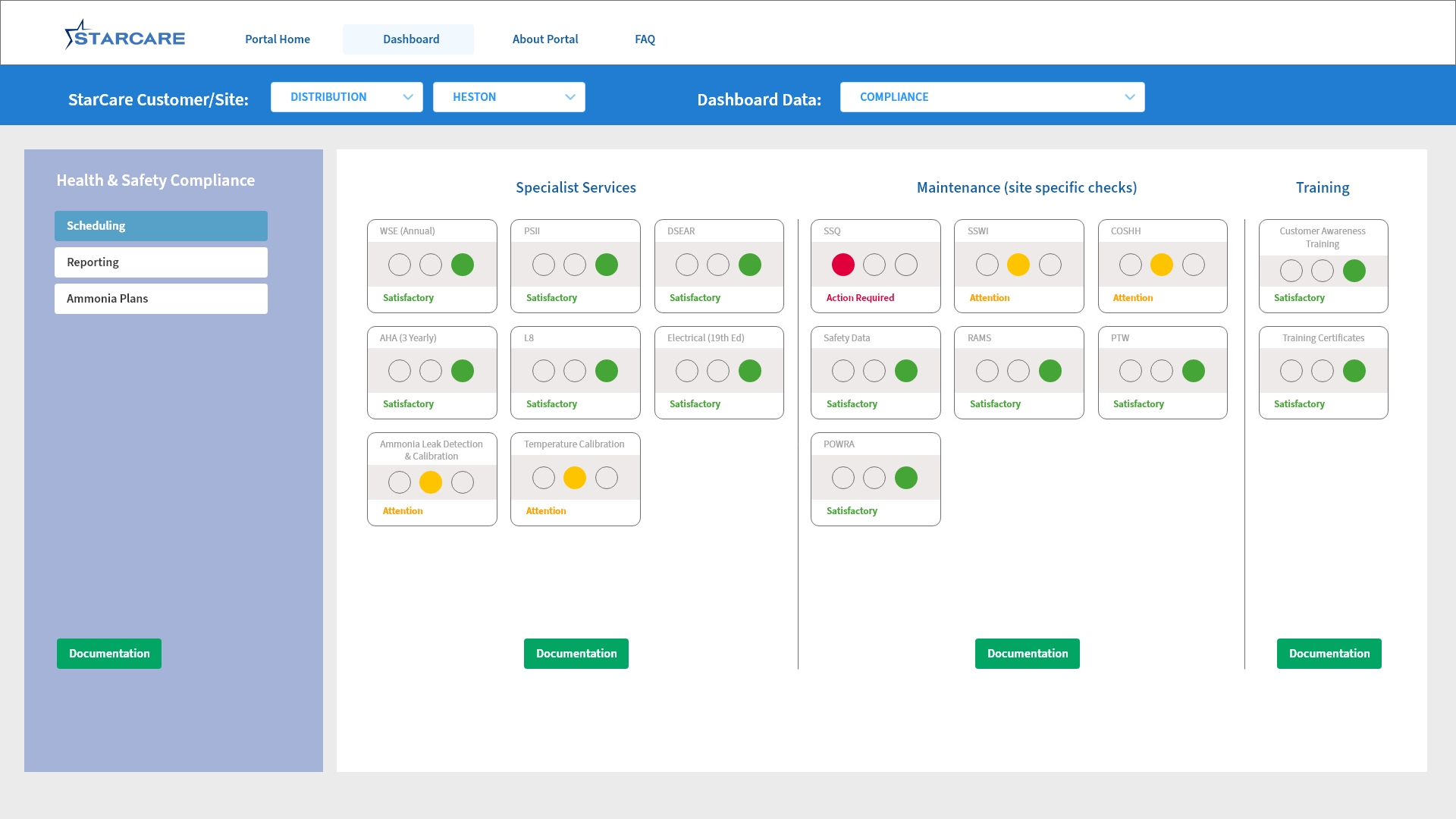

StarCare is Star’s proactive and predictive maintenance service for refrigeration plant and equipment. The comprehensive programme features specialist engineering activities to minimise downtime and help customers to save energy, significantly reducing whole-life costs.

StarCare has recently been boosted by a range of high tech energy-focused services, which enable plant operators to make significant cost savings. Pioneering remote monitoring technology and intelligent data analysis software is now being used to collect, record and analyse all energy-related plant data.

StarCare engineers are using the latest remote monitoring technology to gather up-to-date information on electricity, water and gas utilisation, as well as data on the overall energy cost of the plant. The data is analysed to identify energy saving opportunities and make technical adjustments, whilst specialist software is configured to help optimise energy usage.

Star Refrigeration Head of Key Accounts William Little says: “Traditional PPM providers seldom record energy usage as part of a refrigeration plant maintenance programme, yet it typically amounts to 70% of operating costs.”

William Little adds: “Through high tech data analysis and energy management, our engineers can assess plant efficiency and address performance issues. This enables plant operators to make substantial energy savings, amounting to between 10% to 30% on annual electricity costs.”

Star has introduced specialist software configured with specific energy management protocols to predict and optimise energy usage. By monitoring seasonal ambient temperatures, graphing climatic trends and analysing data, StarCare engineers can adjust controls accordingly to help keep equipment running reliably at optimum performance parameters all year round.

Load shedding and electricity tariff management can also be employed to deliver substantial energy cost benefits to customers. Software allows plant control systems to switch off or shed load during peak periods without compromising temperature or production, to take advantage of reduced tariffs offered by energy suppliers.

As a progressive aftercare provider, Star has continually developed its refrigeration plant maintenance service to ensure maximum operation and efficiency, with minimal disruption to customers. StarCare is specifically designed to minimise downtime, significantly reduce whole-life costs and achieve energy-saving environmental targets.

Star’s highly skilled engineering team offers a comprehensive aftercare service tailored to each customer and every individual site. From annual servicing and basic periodic inspection, to 24/7 alert handling, remote monitoring and capital planning, StarCare is designed to meet each customer’s operational and compliance needs.

The StarCare service is available to customers nationwide through Star’s nine ‘Centres of Excellence’ across the UK. Star has a highly skilled team of over 100 mobile ammonia and F-gas trained industrial refrigeration engineers working across its UK branch network.

For more information, please visit https://www.star-ref.co.uk/smart-thinking/planned-preventative-maintenance-and-asset-management-services/ or contact star@star-ref.co.uk