Author

James Ward

Operations Manager

Why Invest in Planned Preventative Maintenance?

Refrigeration plant is a key business asset which requires investment in an ongoing programme of planned preventative maintenance (PPM).

Traditional PPM features a series of scheduled site visits by refrigeration engineers to ensure equipment safety and reliability. As well as confirming legislative compliance, these regular system health checks help to identify and rectify faults, minimising downtime for end users.

The life expectancy of an industrial refrigeration system is around 20 years, but this figure can be significantly extended through lifelong proactive PPM support. A professional PPM programme can boost system resilience and longevity by continually monitoring performance and making the required technical adjustments. This also helps to increase plant efficiency and reduce operating costs.

What are the Key Features of a PPM Programme?

A basic PPM schedule of works includes:-

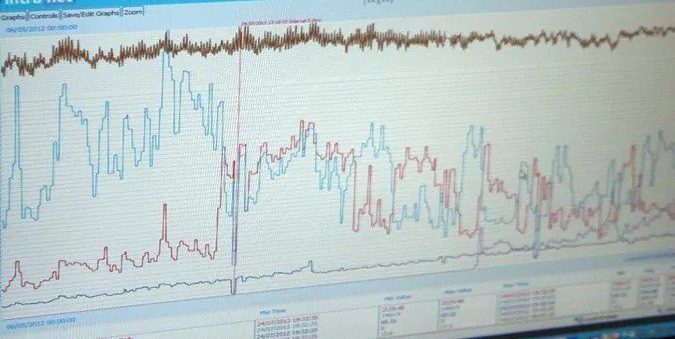

Data extracted from modern PLC control systems, including compressor run hours, load profiles and other condition monitoring parameters, enables better programming of overhauls and other scheduled maintenance works. These control systems can also provide alarms when performance moves away from design parameters and automatically alert operatives to faults.

Operational trends can also be monitored via the on-site PLC, whilst PPM technology has been developed which allows plant performance data to be reviewed remotely via a broadband link.

What is StarCare?

Star Refrigeration’s Operations team provides a full range of proactive maintenance support services, from periodic plant inspection through to StarCare, our professional and proactive PPM programme.

StarCare is an innovative PPM service developed using industry-leading software technology to increase system resilience, prevent plant failure and reduce operating costs. Each tailored StarCare package is designed to minimise downtime, whilst ensuring plant efficiency, safety, reliability and longevity.

Operational data is transmitted via broadband from each customer site to a Central Monitoring Hub in Glasgow, where expert technicians monitor plant condition and review performance on a weekly basis. Customers are provided with ongoing guidance from the StarCare management team and receive locally-delivered proactive maintenance support as required.

Operational data is transmitted via broadband from each customer site to a Central Monitoring Hub in Glasgow, where expert technicians monitor plant condition and review performance on a weekly basis. Customers are provided with ongoing guidance from the StarCare management team and receive locally-delivered proactive maintenance support as required.

The Key Benefits of StarCare Include:-

StarCare 2020 is our latest web-based PPM package. Currently in development, this system will provide customers with an online dashboard featuring comprehensive PPM information. StarCare 2020 will allow 24/7 access to live performance data, trend analysis, operational reports and full documentation.

All StarCare PPM services are delivered by a highly experienced management team, with support from Star Refrigeration’s national network of over 90 engineers from nine UK branch offices.

To find out how StarCare can help your business, click the link to contact your local branch and arrange a visit from our Operations team: https://www.star-ref.co.uk/contact-us/

This article has been certified for Continuing Professional Development (CPD) by The CPD Certification Service. To get your CPD Certificate please email your request to CPDCertificate@star-ref.co.uk