Performance data graphing and trend reports can also be compared with the manufacturer’s design parameters, with targeted adjustments made to improve efficiency and reduce operating costs.

Star has continually refined and improved its condition based maintenance and remote monitoring service over the past two decades. The latest smart technology has been incorporated to develop its StarCare service, the ultimate in condition based PPM for users of industrial cooling across a wide range of sectors. Playing a key role in asset management, StarCare is designed to extend plant life, improve whole life cost and reduce client spend.

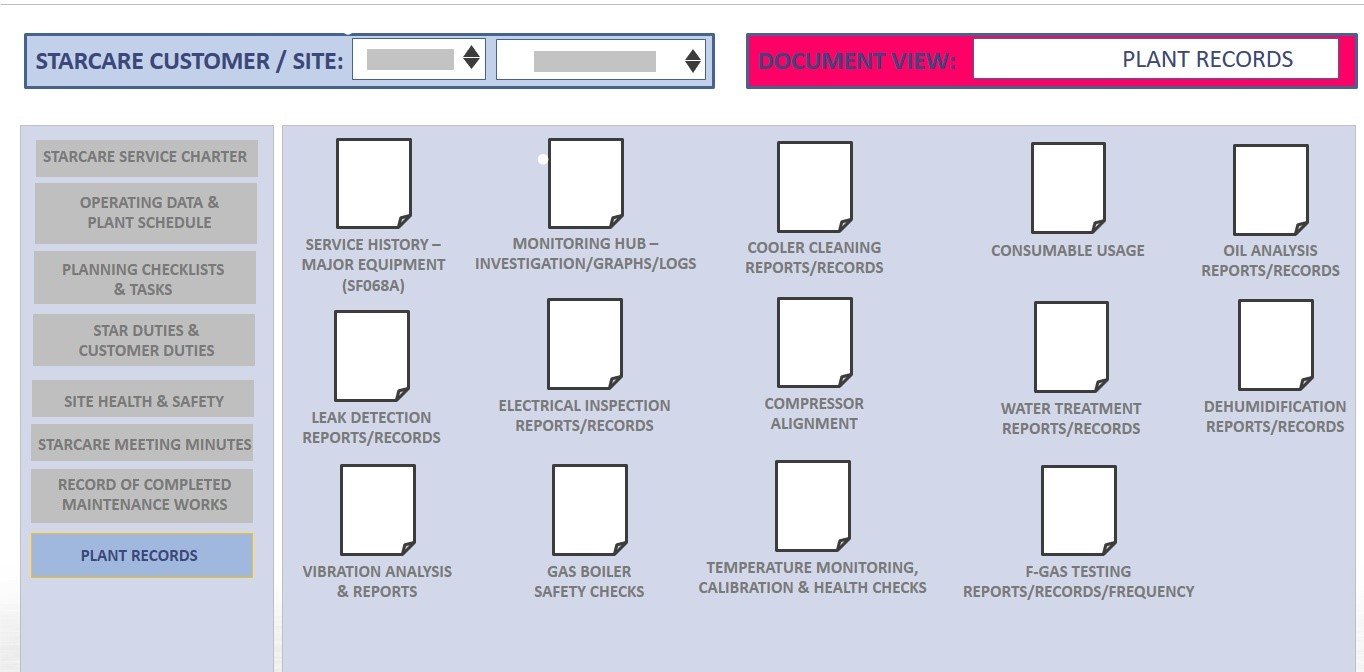

Star has a dedicated StarCare Monitoring Hub at its Glasgow headquarters, which delivers intelligent remote monitoring for industry-leading clients. Focusing on live data analysis, the expert team reviews plant performance and reliability against the plant manufacturer’s optimum design parameters. Condition based maintenance techniques employed include quality checks of refrigerant, oil and glycol, monitoring of electrical current, energy usage and tariff optimisation, vibration monitoring of compressors, motors and pumps, thermographic system scans and airflow monitoring before and after cooler or condenser cleaning. By analysing data from these automated processes, StarCare analysts can make recommendations for engineers to focus on during site visits. Task lists are devised for local engineers to make the appropriate technical adjustments and take action to improve system efficiency.

As well as analysing data to identify current issues and improve performance, sophisticated computer technology now allows the StarCare team to confidently undertake an increasing amount of predictive maintenance. Specialist computer software is used to produce insightful algorithms and trending data, which can be analysed to accurately predict future plant performance and maintenance requirements. As a proactive and predictive PPM programme, StarCare keeps equipment running reliably at optimum performance parameters all year round by monitoring climatic changes and making adjustments to optimise seasonal plant operation and performance. Increasing efficiency enables end users to achieve the best return on their investment by reducing the whole lifecycle cost of the plant. Intelligent data analysis and predictive maintenance also allows plant operators to plan for future capital expenditure, such as component replacement and system overhauls.

Star is continuing to invest in state-of-the-art technology to further improve the proactive and predictive focus of StarCare, its comprehensive and results driven maintenance service. In addition to a dedicated Monitoring Hub, Star provides 24/7 PPM coverage across a national network of nine branch offices, with 10 experienced management teams and over 100 mobile field engineers.

For more information on StarCare, contact: jward@star-ref.co.uk

This article has been certified for Continuing Professional Development (CPD) by The CPD Certification Service. To get your CPD Certificate please email your request to CPDCertificate@star-ref.co.uk