Author

Valgard Bertschinger

Head of Business Development - Operations

Sectors

Freezing and Chilling

Food Manufacturing

Valgard Bertschinger

Head of Business Development - Operations

Freezing and Chilling

Food Manufacturing

Good Document Management and Traceability

Refrigeration plant is a valuable capital asset and an integral part of many multi-million pound temperature controlled business operations.

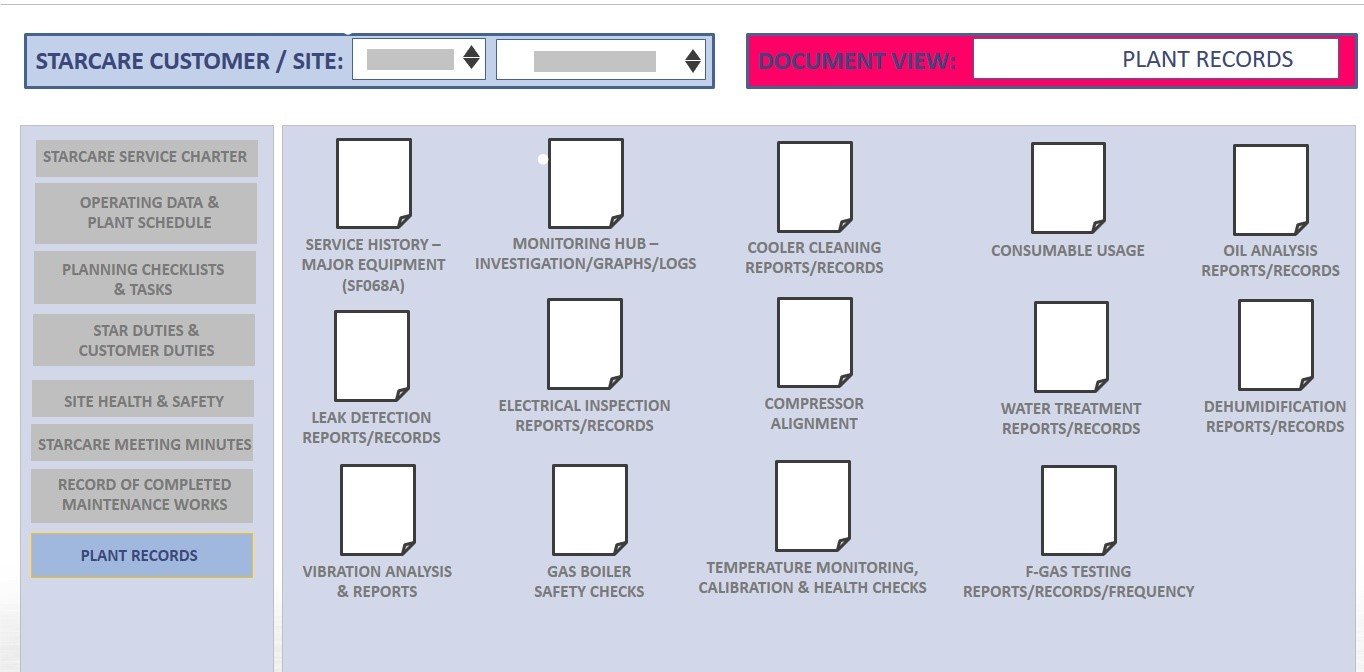

Star Refrigeration’s Operations team has a proactive approach to plant maintenance that is individually tailored to support and protect this key business asset. Central to our service is a digital document management system, which provides customers with a clear picture of plant operation, safety and efficiency, as well as a full maintenance record, including historic and planned activity.

Comprehensive maintenance documentation benefits refrigeration plant operators when they are subject to an inspection by the Health and Safety Executive, Environment Agency or a customer audit. As well as confirming legislative compliance, good documentation demonstrates the effective management and competency of their maintenance service provider.

The traditional approach to plant maintenance documentation was largely reactive, with the completion of a hand-written log book or service record. Engineers carried out basic system checks, manually logging information in various tables to show refrigerant use, oil changes, call outs, component failures, repairs, faults and alerts.

The modern approach to document management sees maintenance moving to a digital platform. During site visits, engineers input information to the required fields on digital worksheets, whilst remote monitoring technology allows us to review records and analyse plant data.

Tailored to each refrigeration plant, Star’s comprehensive digital maintenance record includes all basic system checks and legislative compliance testing, as well as a detailed operational examination. Our engineers undertake regular analyses of vibration levels and oil condition, drive motor and compressor performance, thermographic and air flow measurements, leak detection and general component health.

Once inputted into the mobile device, digital data is submitted for external review by a Service Supervisor. The information is quickly reviewed and analysed, with operational issues identified, areas for improvement determined and solutions proposed.

Maintenance documentation can also be analysed to predict future maintenance requirements to help prevent costly issues developing. Current and historical plant data is used to plan a schedule of proactive engineering works to prevent future problems.

Through digital data analysis, we assist customers with future capital planning, highlighting when budget needs to be allocated for the required expenditure on refrigeration plant. Data can be extracted from maintenance documentation to help operators build a business case to help reduce long term running costs and ensure ongoing reliability.

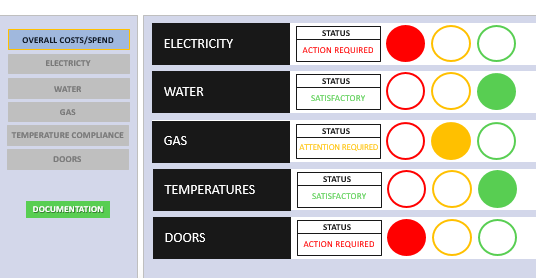

Traditional service providers seldom record energy usage as part of a refrigeration plant maintenance programme. At Star, we believe the value of recording data on energy usage is vital and should not be underestimated. Energy usage is the end user’s greatest expense when it comes to refrigeration plant, typically amounting to around 70% of operating costs. Recording and analysing energy usage allows us to assess plant efficiency and address performance issues in order to save operating costs for our customers.

Even with the highest level of proactive plant maintenance, there can still be a reactive element, where a fault or component issue has unexpectedly developed. In such cases, a retrospective analysis of maintenance documentation can help to identify what could have been done to avoid the situation and prevent it from reoccurring in future.

Investing in ongoing proactive maintenance helps temperature controlled businesses to reduce costs and protect their most valuable asset. Good document management plays a key role in ensuring the continual efficiency, safety and reliability of refrigeration plant.

To find out how Star’s maintenance programmes and digital document management systems could benefit your business, please contact: vbertschinger@star-ref.co.uk

This article has been certified for Continuing Professional Development (CPD) by The CPD Certification Service. To get your CPD Certificate please email your request to CPDCertificate@star-ref.co.uk