The Star SEC Calculator App – the first step on the temperature controlled storage journey to Net Zero

Author

Rob Lamb

Group Sales & Marketing Director

Sectors

Temperature Controlled Storage & Distribution

Rob Lamb

Group Sales & Marketing Director

Temperature Controlled Storage & Distribution

Star Refrigeration free Specific Energy Consumption benchmarking app (SEC Calculator App) launched recently, amidst the build-up to COP26 and much conversation around the need for businesses to meet Climate Change commitments and start on the route to Net Zero.

It feels important to mention the energy climate in which the App launches because there can be the impression gained that the climate emergency is so dire, it’s going to take some awesomely complicated technology to sort it all out. And what can one business do in the face of such depressing statistics and urgent deadlines?

The cooling industry currently accounts for around 10% of global greenhouse gas emissions, and the United Nations Environment Programme (UNEP) is warning that without radical changes, cooling industry HFC emissions are projected to reach 20% of CO2 output in 2050.

UNEP’s Emissions Gap Report 2021 shows that new national climate pledges, combined with other mitigation measures, still put the world on track for a global temperature rise of 2.7 degrees Centigrade by the end of the century. That is well above the goals of the Paris Climate Agreement, and would lead to catastrophic changes in the Earth’s climate.

It’s easy to read statistics and reports such as these and feel that the challenge is insurmountable.

And that, as Professor Katharine Hayhoe (Chief Scientist at The Nature Conservancy) has pointed out, is the exact problem.

“The no. 1 thing that we are missing is a sense of efficacy,” she commented recently at Yahoo Finance’s All Markets Summit. “We don’t think that anything we do will make a difference. But the world has changed before. And when it changed, it was when individual people used their voices to talk about how the world could be different.”

Obviously we are not suggesting that the SEC Calculator App is about to bring about a different world or some sort of climate revolution. And that is the point. It is the small, incremental changes that businesses and individuals make, continuously over a period of time, that will take us on the journey to Net Zero over the next 30 years.

Specific Energy Consumption Benchmarking App

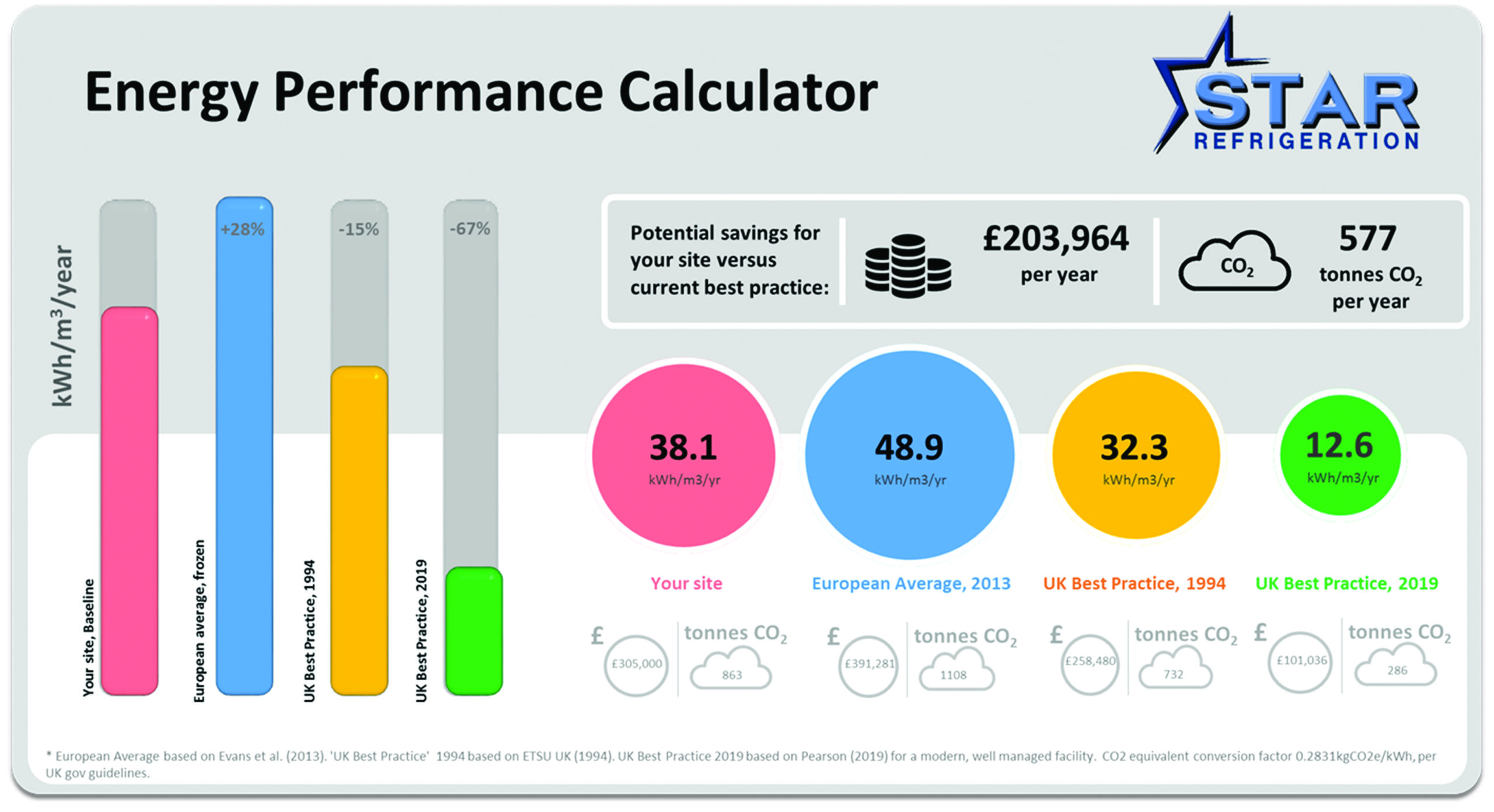

The SEC Calculator App allows temperature controlled storage facility owners to compare their sites’ energy performance against industry Best Practice, and predicts potential energy and CO2 savings. Using it is a simple way of starting the Net Zero journey.

Once the app is downloaded, all that’s required is for the user to input the store type (freezer, chill or mixed) annual energy consumption and the volume. There is also the option to input the price paid per unit of electricity.

The SEC calculator then shows how a plant compares against other sites across the UK and Europe, and what sort of energy, CO2 emission and cost savings are possible by improving the energy efficiency of the site.

The app was a response to recognising that operators needed a metric for which they could understand how well their facility was performing. It uses the method developed by ETSU (Energy Technology Support Unit) in the UK, which reports the energy in kWh of electrical input to the site per annum, divided by the cubic volume of the refrigerated space. This is known as ‘Specific Energy Consumption’.

Using Specific Energy Consumption allows cold chain businesses to compare and benchmark their energy consumption to industry standards – seeing at a glance how their facility compares to other refrigeration plants and UK best practice.

The SEC Calculator App means that through benchmarking businesses can start to understand what good looks like – taking ownership of their energy use whether good, bad or indifferent.

Variations in cold store efficiency

Since the introduction of the Climate Change Agreement (CCA), the cold chain industry has performed well as a whole at reducing energy use. 2018, for example, showed a 16% year-on-year improvement compared to 2017. The CCA target for that period was just 9.6%, demonstrating how impressively the industry performed.

However, although this ‘big picture’ for the industry as a whole looks good, the fact is that not all its component parts are pulling in the same direction. 55% of the units surveyed in that 2017/18 period exceeded their objectives, contributing to the strong overall performance. At the same time, the same study revealed that 45% of businesses did not achieve their goals, highlighting how much more work lies ahead in reaching a net zero future.

Using the SEC Calculator App lets you know whereabouts your store sits on this sliding scale. This is the first step, which consequently allows businesses to act upon that knowledge and take the next steps to cut running costs, along with reducing their carbon footprint.

Performance optimisation

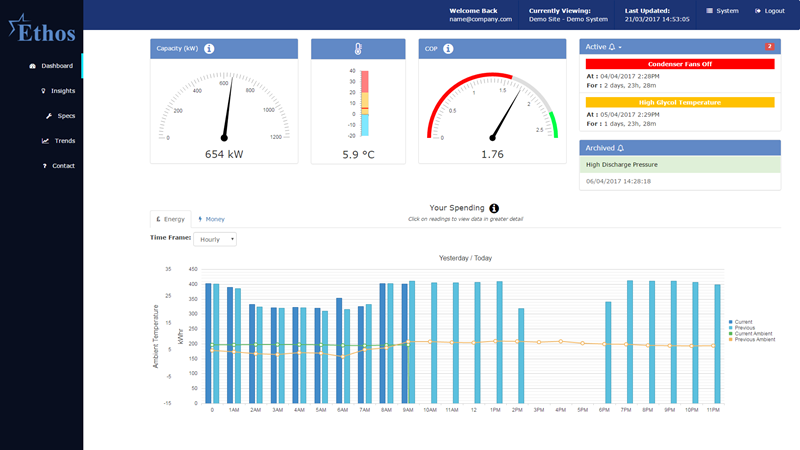

Measuring a store’s performance using a smart data monitoring system such as Ethos is the second step on the road to Net Zero.

In temperature controlled storage settings it has often been difficult to assess the effectiveness of improvement initiatives due to the large daily variations in system load and weather conditions. This is one of the reasons why there has previously been a lack of uptake on new monitoring and control technologies. Without a universally recognised definition of store efficiency, it is difficult to know how effective they are.

The ability to comprehensively measure store efficiency can be achieved through a performance optimisation service, such as Ethos. This data-led system measures the performance of facilities by collecting data from refrigeration plants in real time, and comparing actual operating performance with a computer model of theoretical performance (the ‘digital twin’).

The smart monitoring this provides highlights any energy gap and enables the team at SDA (Star Data Analytics) to identify problems and suggest corrective actions, ensuring that systems operate in an optimised manner. Owners and operators of cold storage facilities will therefore be able to take the smart route to reducing energy usage and meeting environmental goals.

Assess Opportunities for Improvement

The third step is to use the knowledge you have gained so far to assess opportunities for improvement.

Smart data monitoring technology is able to find hidden energy saving optimisations even on well-maintained plants. Quick wins can be plant related including fixing damaged or underperforming components or tweaking control setpoints. Some might be operational related issues such as improved door control or repairing damaged dock doors. Other changes can be integrated with current maintenance activity or made through already planned capital investment, such as control upgrades and component overhauls.

These savings and changes were identified using real time data analysis to measure and compare each plant with the original design expectations. Data from over 50 live installations indicates that this saves the plant between 10% and 30% of annual running costs, helping to move operators along the road to Net Zero. An example of a recent project in which Star’s perfomance optimisation system, Ethos, was used to save Asda 5GWh on energy costs and 1,100 tonnes of CO2 emissions can be found here.

Systems such as Ethos allows temperature controlled facility operators to assess the financial effectiveness of performing maintenance on industrial refrigeration systems – enabling a payback against the cost of conducting the maintenance to be calculated.

Reduce Energy Consumption, Increase Reliability and Remain Compliant

The fourth step along this roadmap to Net Zero is to begin and continue reducing energy consumption – at the same time as increasing reliability and remaining compliant with legislation.

Implementing recommendations from a data monitoring and performance optimisation programme can help you to meet your Climate Change Agreement (CCA) targets by reducing running costs. This can ensure that your facility receives a 92% reduction on the Climate Change Levy.

Comparing an average cold store energy consumption of 50kWh/m3/yr from the European ICE project (Evans et al, 2013) with that of best practice 10kWh/m3/yr (Pearson 2019) shows that there can often be a factor of 5 between the average cold store energy use and best practice. Given the rocketing price of energy, it’s clear that poor control of energy use can make the difference between profit and loss for an organisation – and between meeting your CCA targets, and not.

The backdrop of COP26 implies that large action is required – and indeed on some level it is. However, it is also all the small actions that add up to the sum of the whole. For example, one of the benefits of using monitoring technology is that it gives the store operator confidence in the reliability of the operation. This means that they can take supposedly small (but actually highly significant) actions such as raising the temperature setpoint of the facility. Sometimes temperature targets are set lower than necessary in order to provide a perceived buffer against unreliable operation. When this is no longer necessary, further emissions and cost savings can be made.

Having robust planned preventative maintenance will also help to ensure reliability and avoid unexpected costs for repair and downtime. This should include future planning in terms of capital expenditure of overhauls, repairs and replacement.

From PSII inspections to ammonia hazard assessments, it’s important to know that your equipment is safe to operate and in line with current requirements. Failure to do so could put staff and contractors at risk in terms of health and safety and ultimately be a risk to your company’s future existence.

Final step: Track Progress and Continuous Improvement

Taking the initial action of benchmarking using the SEC Calculator App, followed by performance optimisation, assessing areas for improvement and making energy reductions, all add up to robust action for yourself as a business and the planet as a whole.

The effects of any improvements should be continuously monitored, ensuring you are in the best position possible to meet or exceed 2050 Net Zero targets.

In addition to submitting annual numbers via the annual CCF report, owners and operators will be able to look at running costs and take actions that increase plant longevity. A well-maintained refrigeration plant increases the system’s lifespan, which brings down energy costs and represents huge environmental savings.

Meeting Net Zero targets

The smart road to Net Zero is a journey over the next 30 years, combining the use of modern efficient equipment with continuous monitoring, proactive maintenance programmes and compliance with legislation. Choosing the right support mechanism available such as the SEC app, low carbon cooling solutions, StarCare maintenance programmes and Ethos energy optimisation software, provides both an understanding of how your plant compares to others and best practice, and the data-driven continuous assessment that leads to ultimate performance optimisation for refrigeration plant and chilled distribution centers.

The SEC Calculator app is available on iOS and Android app stores and if you are viewing on your phone can be downloaded here:

Alternatively, you can download the app by searching ‘SEC Calculator’ in the app store.

References:

This article has been certified for Continuing Professional Development (CPD) by The CPD Certification Service. To get your CPD Certificate please email your request to CPDCertificate@star-ref.co.uk