The technology that will shape the future of the Cold Chain

Author

Rob Lamb

Group Sales and Marketing Director

rlamb@star-ref.co.uk

Sectors

Temperature Controlled Storage & Distribution

Food Manufacturing

Rob Lamb

Group Sales and Marketing Director

rlamb@star-ref.co.uk

Temperature Controlled Storage & Distribution

Food Manufacturing

Increasing global temperatures and energy costs, along with a scarcity of resources are forcing changes in our approach to power consumption in the cold chain. There is a need to adapt in order to continue to deliver product to customers cost effectively and also meet evermore challenging environmental targets.

Electrical power used by refrigeration typically represents the largest energy consumer for a temperature controlled facility. Despite this, a study of several hundred cold stores across Europe indicated that many are consuming far more kilowatts hours of energy when compared to ‘Best Practice’ guidance dating from 1994.

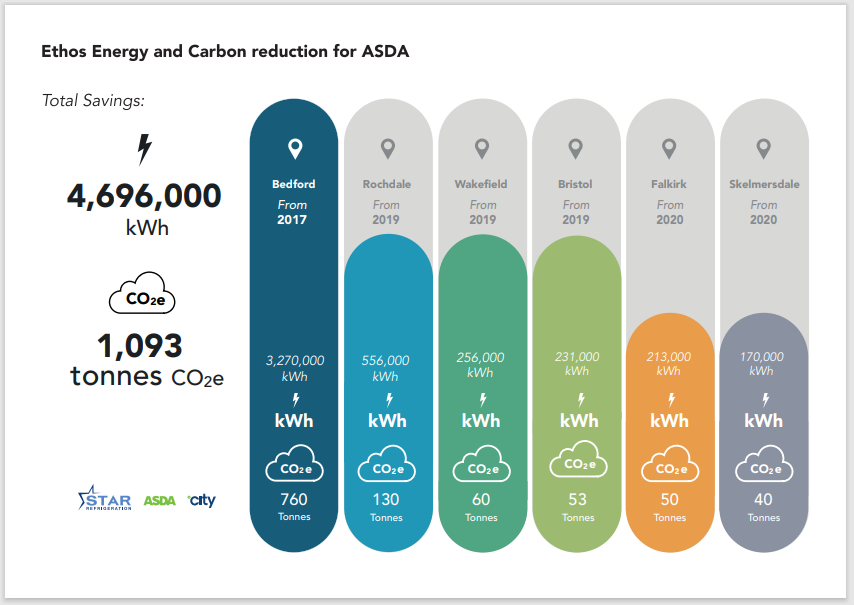

The move towards Net Zero is likely to see increased focus on benchmarking and meeting sustainability goals. This may well set targets for existing operators in terms of improving current performance through a mix of operational changes, infrastructure improvements and implementation of new technology. Case studies have demonstrated that existing facilities can reduce energy consumption by 20% to 30% through the application of modern, innovative technology.

The focus on benchmarking will hopefully drive higher standards when designing new warehouses both in terms of design efficiencies but also ongoing performance monitoring. Recent projects have indicated that new facilities can reduce energy consumption by as much as 85% when compared to existing facilities of the same volume.

When designing new facilities it is important to firstly aim to reduce the potential for heat gain into the building. When it comes to lowering heat gain in buildings, refrigeration plant owners can employ a number of approaches that will make a significant impact. This could include building location and orientation. The number and type of doors from ambient into the facility also have a significant effect in reducing the potential for air infiltration. Selecting the optimum construction materials and thickness is also important. Operation of the store should also be taken into account, finding ways that reduce the possibility and duration of warm air infiltration into cold spaces.

Finally, it is important to select refrigeration equipment that will remove heat from the building as efficiently as possible. This should take into consideration future needs as well as the present. An example is ambient conditions, with peak summer temperatures of +40°C or higher possible in the UK in the coming decade. It’s crucial that cooling equipment can deliver design cooling capacity at these conditions but also operate reliably and efficiently throughout the year when ambient temperatures are lower and could drop below 0°C in winter months.

The issue of water availability should also be considered as this becomes scarce and potentially more expensive. Air cooled refrigeration plant consumes more energy than an evaporative system at peak summer conditions. However, studies have shown that for a temperate environment like the UK, the annual energy consumption for air cooled plant is lower and avoids the need for expensive water treatment.

Changing F-gas regulation has seen the phasing down of synthetic refrigerants, with many in the industry now turning to natural alternatives, such as ammonia and CO2. Since F-gas measures were introduced back in 2015, the sector has seen a 55% cut in the amount of carbon emissions, with a 69% reduction having been prescribed by 2024 and 76% by 2027. However, new European draft legislation is expected to bring forward the 2027 target cut to 2024. The European Commission, Parliament and Council are still to decide on the final targets but it seems that the end goal will be to achieve a 95% reduction in carbon dioxide emitting refrigerants by the year 2030 and a full phase-out by 2050. The draft report also proposed bans on HFCs and HFOs with higher GWPs in multiple applications, such as split heat pumps and stationary refrigeration equipment, from 1st January 2028 and 1st January 2027 respectively.

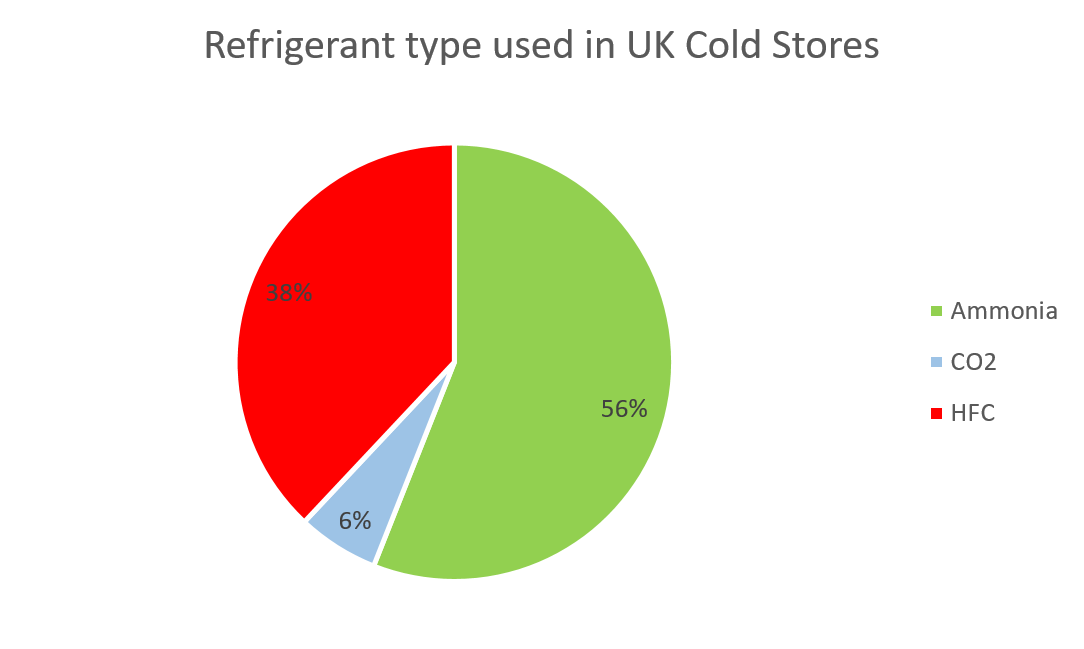

The Cold Chain Report 2022 by the Cold chain Federation data shows that 38% of cold stores are still running on HFC refrigerants but with the incoming F-gas regulation and the 2050 Net Zero goals in mind, natural refrigerants like ammonia and carbon dioxide, are expected to take a bigger share of the market.

Automation will also play a role in driving through more energy savings, though skilled engineers will be needed in order to achieve this goal.

When good practice is not adhered to, energy loss goes up, raising bills and impacting on the profits of cooling plant facilities. This is a particularly pertinent factor, especially as energy costs are spiralling but it can be somewhat mitigated with the flexible packaged cooling solutions now coming onto the market, that allow for the relocation of the plant anywhere, making it an asset for the organisation rather than cost.

Operations such as blast freezing are currently quite inefficient, with typical required running temperatures averaging at -40 degree C, a heavy energy load. However, emerging technologies are showing promise in improving efficiency in this area, by making it possible to perform the entire process inside the cold store. This will allow for much greater efficiency as it will mean that product will not have to be continually moved in and out of blast freezers.

The cooling sector also has a potential role to play in vertical farming, a continually evolving process that maximises the use of space and tackles the shortage of arable land and the produce waste. It will be exciting to see how refrigeration innovation can aid vertical farming’s expansion.

In terms of renewable energy, there will be a shift to carbon free production of power, with greater use of technologies such as hydrogen power, wind and solar power. Even hydrogen can be produced on site or locally and ammonia can be used as a feed source for this.

Big data will also be pivotal to identifying new ways to lower energy consumption. The cooling sector has historically tended to look back in hindsight but with the increased ability to continually monitor readily available operations’ data, necessary changes can be identified and made at speed.

Projected models, which examine potential future systems performance and make energy usage predictions into the future, can help to identify shortfalls and challenges, while benchmarking can be used to prioritise legislative targets.

Feeding ambient weather data into projected site energy consumption predictions will help plant owners decide what should be kept running and what should be switched off to balance power consumption.

Gigawatts of energy can also be saved in the waste recycling process, via the proper application of cooling technologies. Heat captured from the cooling process can also be used to supply heat to other locations, such as business parks and residential housing blocks.

By diverting lost heat into district heating networks and linking cooling and heating, we can transform what is currently classed as waste into viable energy and possible revenue stream.

Moving forward, in order to achieve greater sustainability and address the increasing global challenges, the cooling industry must emphasize enhancing facility efficiency throughout a site’s entire lifecycle, rather than solely focusing on the point of installation and the initial years.

One last final thought: Socrates once stated that “the secret of change is to focus all your energy not on fighting the old but on building the new.” This wisdom reminds us that instead of resisting the past, we should direct our efforts towards creating a better future.