Expensive capital equipment requires a programme of planned preventative maintenance in order to obtain maximum asset life, safety, reliability and performance. Refrigeration equipment maintenance has traditionally been done by a programme of planned site visits by engineering specialists. During the course of a visit, a series of maintenance and performance health checks would be carried out and immediate adjustments made to correct any deviations outside of performance parameters.

Star Refrigeration pioneered this methodology under the StarCare brand and, while this has been considered best engineering practice, it can be considered costly due to the number of site visits by the refrigeration engineering specialist.

Recognising the need to provide our customers with significant cost efficiencies – but without a reduction in safety or service quality – we invested in a development project to examine alternative, reduced cost methods.

We sought innovative solutions for monitoring the condition of key assets and predicting time frames for maintenance. With very large, complex refrigeration systems, our main goal was to manage maintenance and refurbishment efficiently and to provide early warning of any deterioration.

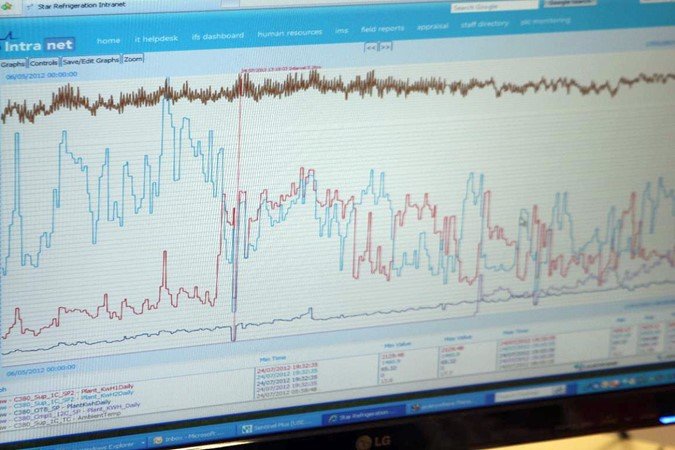

Our solution was to develop and implement a monitoring system that can review plant performance data. This is done via our on-site Telstar and Sentinel alarm systems, which harness key system data and transfer it to a Central Monitoring Hub to be measured, monitored & managed.

Key benefits include:

- Smart use of existing control hardware and software

- Collect key data remotely instead of unnecessary engineer site visits

- Plot performance metrics against pre-set bands via alarm software

- Provide trend data for interpretation via graphing software

- Provide exceptional customised customer reports

Data is transmitted via broadband link to our Central Monitoring Hub in Glasgow, whilst our intelligent infrastructure system also allows local branch technicians to filter out specific alarms and alerts from site.

Once data is collected by the local branch, the maintenance managers can then predict the following week’s maintenance requirements, so as to minimise downtime.