It’s difficult to find out exactly how much you spend on cooling and heating, as the costs are often hidden in the total electricity bill. But, did you know that 90% of energy costs in the cold storage sector can be attributed to refrigeration? Or that the majority of businesses which require cooling can often spend over 50% of their electricity bill on cooling?Star has decades of experience in the energy management of refrigeration systems, both in the specification of new plant and the improvement and optimisation of existing system performance.

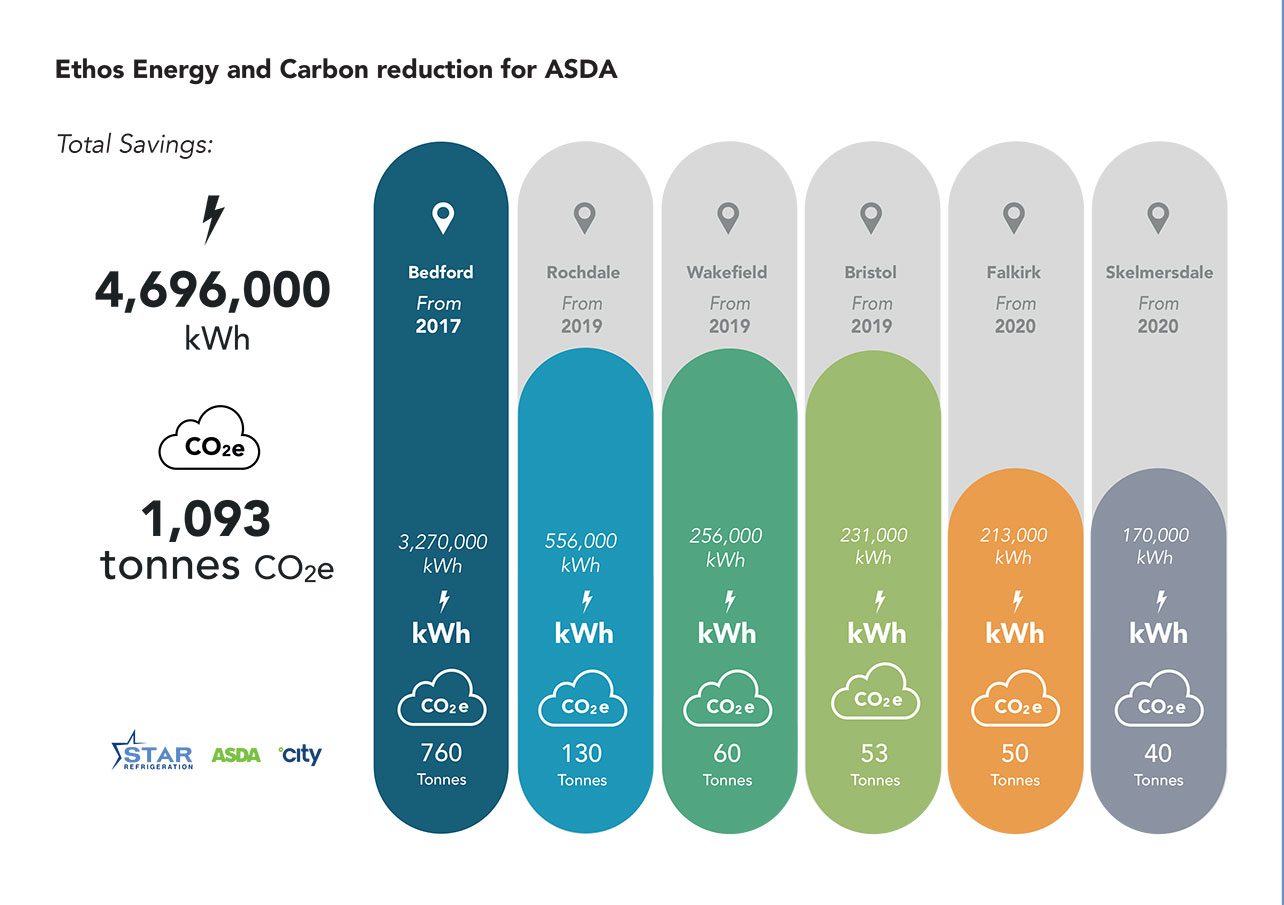

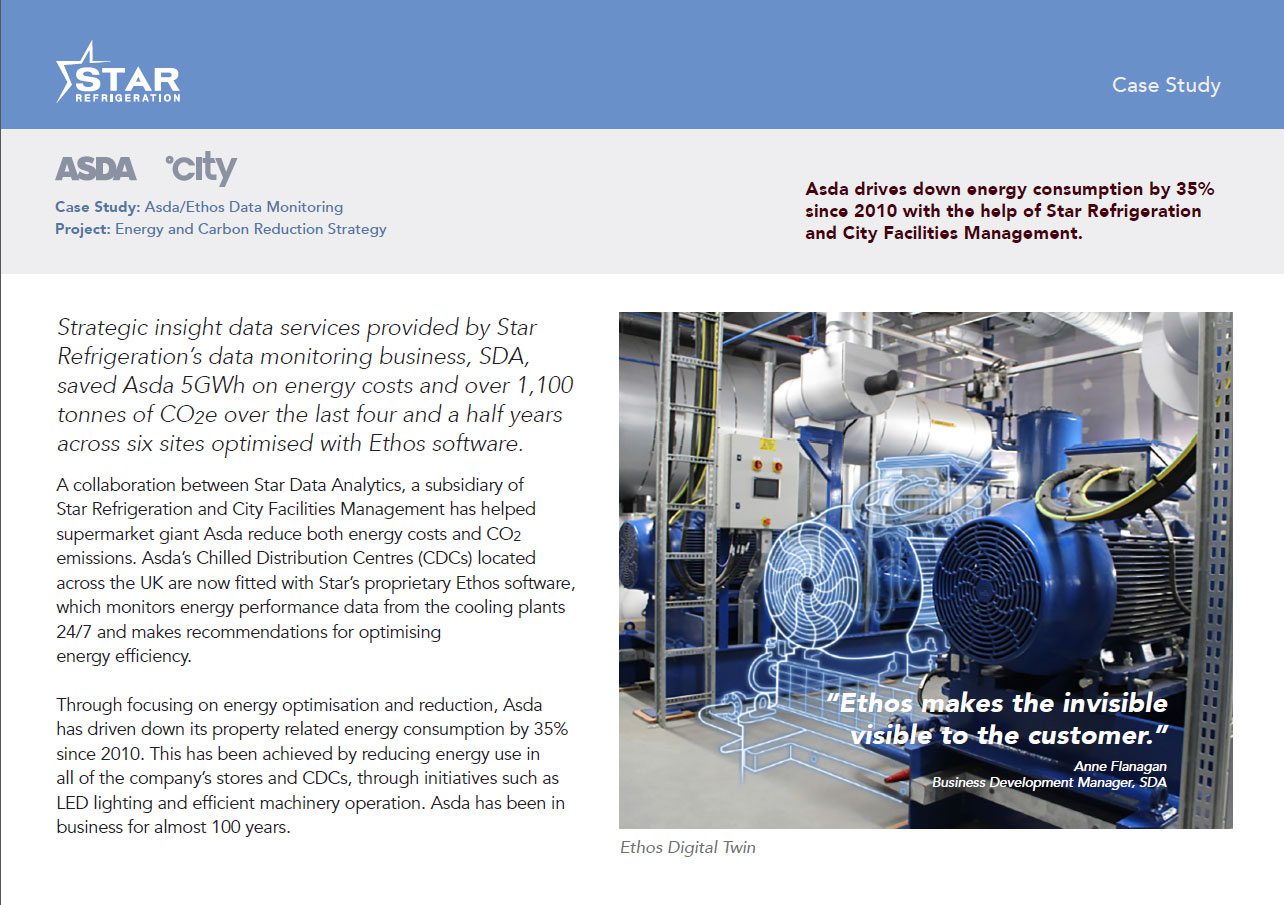

The easiest opportunity for ensuring low refrigeration plant energy consumption is through intelligent design at the planning and purchase phase, however it is more difficult to ensure optimised performance of existing systems on an ongoing basis. With this in mind, Star have developed a specialist performance optimisation and energy management system (Ethos) which allows plant owners to reduce their energy bill and break down energy costs, as well as understand consumption and take steps to make the refrigeration plant more efficient and less costly for their business.

By using Star’s Ethos, you have total control over performance and efficiency. Our refrigeration experts remotely monitor the equipment and constantly analyse it to report back to you. Cooling experts will explain everything in simple terms, then make recommendations for corrective actions which could have a significant impact on your energy bill. Typically, achievable savings are between 10 to 30 %, with little associated cost since large investment is not always necessary to implement the improvements.

Ethos remotely monitors refrigeration systems by collecting data and carrying out specialised analysis to provide meaningful advice on improving efficiency, saving money and making better informed decisions. As well as benefiting from a reduced electricity bill, your business will demonstrate sustainability by reducing its carbon footprint.

All of your plant data will be available to you, jargon-free, through an online dashboard so that you can constantly monitor which parts of the plant are operating efficiently and which areas could be improved. By taking the recommended actions, you’ll instantly reduce power consumption and start increasing profit margins. The reports are also helpful for determining spare capacity and benchmarking progress before and after remedial action.

This data-driven, bespoke approach to each plant can be deployed for both existing and new sites.